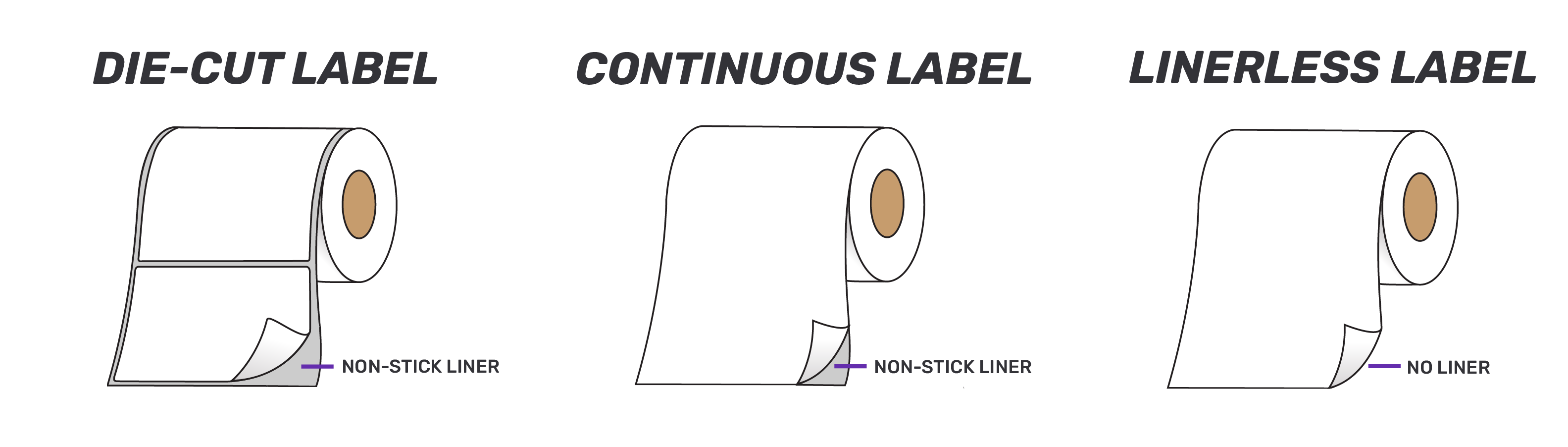

Knowing the right type of scale label to use for your printing process is essential. Why? You want a label that’s not only efficient for your retail business, but one that’s best utilized for your products. And there’s a few options to choose from: die cut, continuous, and linerless.

Each label type is direct thermal and comes with its own benefits. Plus most scale printers are able to handle more than one option, like both die cut and continuous.

So do you know which is the best choice for you?

Let’s look at the label types available and see which option gets the most use for you, your business, and your products.

Die Cut Labels

Die cut labels are individually precut with specific dimensions, depending on the label size you need. This design leaves a small space in between each label. Gaps or black timing marks in between labels help printers determine where each label starts and ends.

Because die cut labels are a traditional label stock, most scale printers are compatible with printing them. They’re easily peeled and applied as labels don’t need to be torn by the tear bar. This makes for a quick, repeatable process and less time wasted cleaning the tear bar.

Die cut labels will almost always be used in peel and present mode. Small and large batches of labels can efficiently be printed if users desire. Just remember that the release liner will need to be thrown away, which adds to waste.

Advantages with Die Cut Labels

- Quick and easily repeatable printing process

- Ideal for peel and present mode

- Compatible with most scale printer models

- Efficient for large or small batches of labels

- No tear bar cleaning

Disadvantages with Die Cut Labels

- Pre-determine label size leaves limited space to print additional information

- Various label sizes needed for multiple options

- Underutilizing label space can be wasteful

- Printer needs to be calibrated when new labels are loaded

- Frequent roll changeover creates additional downtime

Why You Should Use Die Cut Scale Labels

Die cut labels provide users with the widest variety of scale labels to choose from: blank or preprinted. Other scale label types like continuous and linerless don’t have preprinted options.

Die cut labels are best utilized in food and retail businesses where products are weighed and priced, like grocery stores, delis, bakeries, and more. And there’s a variety of options for retailers to choose from:

- Safe Handling

- Thank You & Safe Handling

- UPC Only

- UPC Ingredient

- UPC Safe Handling

Users simply need to print variable information for each product in the designated spaces provided. This is extremely beneficial for products that require important information, like food safety.

For example, butcheries and meat departments must apply safe handling labels to raw meat or poultry products.

Continuous Labels

Just like the name states, continuous labels are…well, continuous! Sometimes called continuous strip labels, they’re one long piece of material on a release liner. Labels are sized to the user’s desired length instead of using predetermined designs like with die cut labels.

This means continuous labels are customizable for easier, on-demand printing.

Most scale printers are compatible with printing continuous labels. After the labels print, labels are torn using the tear bar or an auto cutter (if applicable with the printer).

Advantages with Continuous Labels

- Compatible with most scale printer models

- No calibration needed so labels can start printing right away

- Ability to print in a wide range of label lengths

- Don’t need to buy or store multiple label stocks

Disadvantages with Continuous Labels

- Can contribute to high waste if labels are not formatted correctly

- Only offers blank options – no preprints available

- Label width cannot be customized – only length

Why Use Continuous Scale Labels

Continuous scale labels provide users with customizable options for a wide variety of label lengths. Users can print scale labels for multiple products without having to switch rolls for different sizes.

Continuous labels are best utilized in food and retail businesses where products are weighed and priced, like grocery stores, delis, butcheries, bakeries, and more.

Added label length is beneficial for scale labels that need to be printed with a lot of information. For example, UPC Ingredient and UPC safe handling labels need to include:

- Prices

- Weights

- Important dates

- Barcodes

- Ingredient list or safety instructions

Longer labels can also be used to seal packages for both hot or cold products. Or users can limit material waste by reducing empty space on labels. This allows them to print the same amount of information while saving money on costs.

Linerless Labels

Linerless labels are exactly that – labels without a release liner. They’re manufactured as one long piece of material, like a continuous label.

Linerless labels have a special silicone coating on the material. The coating prevents labels from sticking to each other, similar to a roll of tape. This way labels easily peel away from each other with no liner needed.

And like continuous labels, linerless labels are not pre cut. They can be printed at any length for a wide variety of customized, on-demand label sizes.

Advantages with Linerless Labels

- Ability to customize label lengths

- Environmentally friendly option

- More rolls per label for less frequent changeovers

- Eliminates time associated with disposing liner waste

- Less space needed to store labels

- Don’t need to buy or store multiple label stocks

Disadvantages with Linerless Labels

- Limited printer model options – must be linerless specific

- Only offers blank options – no preprints

- Label width cannot be customized – only length

- Higher maintenance due to adhesive buildup on cutter

Why Use Linerless Scale Labels

Linerless scale labels are beneficial for users looking to flexible label sizes while being environmentally friendly.

Because they lack a release liner, linerless scale labels are highly efficient for speed. Food and retail environments like grocery stores and restaurants benefit the most from these labels.

Deli, meat and bakery departments can print a variety of product information, like:

- Prices

- Weights

- Important dates

- Barcodes

Linerless scale labels in these environments offer customizable lengths to fit extensive amounts of information. This benefits options like UPC Ingredient and UPC Safe Handling labels that print a lot of text.

Restaurants can print receipt-like labels that can be applied directly to orders. This information includes:

- Customer names

- Order numbers & specifications

- Order dates & times

- Prices

Longer labels can also be used to seal packages for both hot or cold products in both environments. Or users can limit material waste by reducing empty space on labels. This allows them to print the same amount of information while saving money on costs.

Printer Compatibility With Your Scale Labels

Now that you’re more familiar with the different scale label types, you can’t forget about your scale printer!

Remember, scale printers won’t be able handle all of these label types. And depending on the scale label you want to use, you may have to buy a specific model.

Check with your scale printer provider to see which types of labels your printer can handle!

Make Pinnacle Labels Your Scale Label Source

Pinnacle Labels is here to help you find the perfect scale label for your business!

We offer a wide variety of scale label sizes and preprints to help meet all of your labeling needs.

Shop pinnaclelabels.com to view our selection of die cut, continuous, and linerless scale label options. Have questions? Give us a call at 1-800-955-5555 or email us at info@pinnaclelabels.com.